4 Reasons Your Lathe Machine Needs Regular Maintenance Support

19 Nov 21

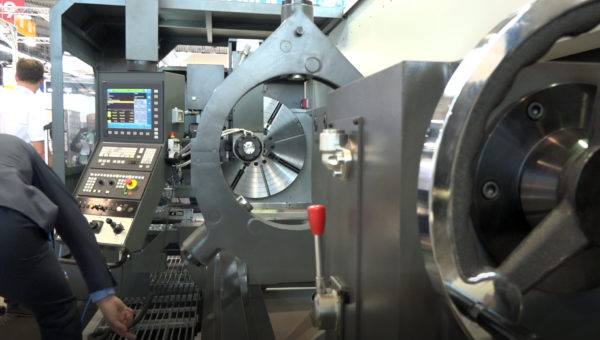

If you have or use a lathe machine, you should be aware of their regular maintenance. You should check any heavy machinery frequently to ensure the safety of the user. Not to mention the cost of having to replace machinery that could be prevented through proper maintenance.

You should be checking over your lathe machine monthly for any minor maintenance and complete maintenance check every six months. We offer lathe machine maintenance services at DTS, providing our customers with high-quality, dependable aftercare and repairs.

We are going to explain the four most important reasons why you should regularly maintain your lathe machine.

1. Reliability

You are using your lathe machine daily, which means that you need it to perform reliably. If you do so, then you will avoid wasting valuable time dealing with damaged equipment. It is more cost-effective to regularly check the function of your lathe machine than the costly process of replacing the equipment.

Most significantly, the more unreliable machinery becomes, the more dangerous it is for the person operating it. Workers can end up seriously injured from machine malfunction, resulting in them taking long periods off work or potentially not returning to work.

By diagnosing issues early, you can resolve them quickly and safely, keeping your lathe machine functioning at its best at all times.

2. Cost

An entirely new piece of lathe machinery can cost up to £40,000. If the cause for replacement is general wear and tear, then it will only be a matter of time before it will require another replacement.

As a business that carries heavy machinery, you should be insured for injury caused by your machines. Properly maintained and certified machinery protects you from potential damage caused to your building or employees. Without it, you could end up paying massive amounts in legal fees as well as taking a hit to your reputation as a business.

If you require a new piece of lathe machinery, then DTS has a wide range, from GEMINIS CNC to Prodesign and Turret lathes. We can install and service your new machine to ensure you get the best out of your lathe.

3. Wear and Tear

Your lathe machine is likely to be used daily. If so, then general wear and tear are completely normal and unavoidable. It makes it all the more vital that you keep up to date with how well it operates.

It is essential to implement good practices within your workforce to frequently and safely conduct regular and minor maintenance. Checking driving belts, lubricant, and coolant levels are small measures you can undertake to ensure your lathe machine is working optimally.

By regularly checking your lathe machine, you will be more likely to spot more severe damage. If this is the case, it is crucial to contact your maintenance contractor urgently.

4. Health and Safety

Employees that work with heavy lathe machinery are at constant risk of injury. Accidents can occur even if your machine is in complete working order and well maintained. Proper machine maintenance must be carried out regularly by experienced and certified professionals.

650,000 non-fatal industrial injuries were reported in 2018/19, with 15% to 20% of these accidents resulting from neglected machinery. Without the regular maintenance of your lathe machinery, you will likely get your license revoked and even possibly have to pay a fine.

Here at DTS, we are fully certified by UKAS, MTA, and Safe Contractor approved. So, you can be sure that we will maintain your machinery to the highest standard. You can check out all our accreditations here.

If you have any questions about your current lathe machine, we are happy to offer a complete service. Likewise, if you wish to inquire about any of our other services, such as lathe machine replacement and aftercare, then please contact us on 03302 234567.