6 Key Mistakes To Avoid When Using A Lathe Machine

22 Dec 21

Lathe machines are heavy, fast-moving pieces of machinery. This makes them incredibly dangerous to use, even by somebody fully trained.

Several risks arise when using a lathe machine. For example, clothing can become trapped within the mechanisms leading to potentially fatal accidents. Wood and metalwork require a lot of skill and knowledge of a lathe machine. It is essential that when using a lathe, you are giving all of your attention and not becoming too comfortable with the process because this is when accidents occur.

DTS UK is here to help you get started with your lathe machine, whether you’re considering purchasing one or getting to grips with your new machine. Here you can find a guide to the most significant mistakes you must be cautious of and avoid when using your lathe machine. As well as the answers to your most frequently asked questions regarding lathes.

What is a Lathe Machine?

Before we dive into the key mistakes to avoid when using a lathe, let’s briefly define the machine for those unaware of what it is or does.

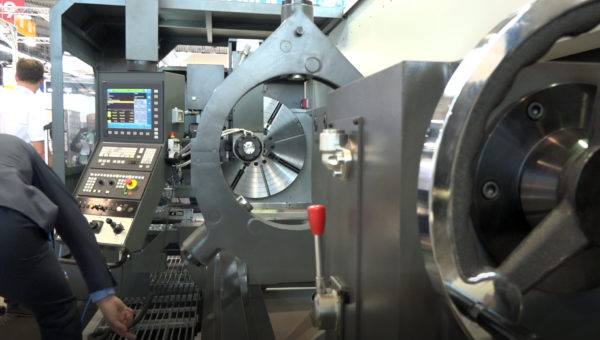

Lathes are machines used in manufacturing to create precise cuts for the production of small or intricate parts. They rotate the workpiece around the cutting tool, shaving off excess pieces in ‘chips’. Your lathe machine can help you shape, sand, turn and cut your workpiece.

6 Mistakes to Avoid When Using a Lathe

There are a few common mistakes made when using a cutting machine. Suppose tools and materials are not correctly secured to the lathe. In that case, they can come loose and possibly hit the user or their colleagues. It is essential to be aware of the potential dangers and ways to avoid them to keep you and your workforce safe. For reference, here are the top six key mistakes to avoid when using a lathe machine.

1. Your Machine Setting Is Too Fast

Your lathe machine can operate at various speeds depending on what material you are using. Changing the speed of your lathe can result in your setting being too fast for cutting threads. Maintaining the right speed and feed of your lathe machine is crucial. Like a car, it can quickly lose control when a lathe is working at an increased rate. This makes the cutting process more difficult and even dangerous.

2. You Are Cutting Too Slowly

Not only will a slow cutting process affect the quality of your workpiece, but it can also increase friction, causing excess heat. Having the correct speed ensures a clean and precise cut, which you aim for when making a high-quality product. Setting the machine too slow limits its performance and potentially damages your work. The added friction also increases fire risk, mainly when working with wood, putting the user’s safety at an increased risk.

3. Lack of Maintenance

Failure to properly maintain your lathe machine is one of the biggest mistakes you can make. If you use a device that is not regularly serviced and repaired, you will lose your safety certification and put users at extreme risk. Faulty lathes can lead to costly replacements or worse payouts for workplace injuries.

Every machine should be cleaned and maintained regularly to avoid any issues. We offer a full lathe maintenance service at DTS, including repairing machine tools, alignment, and laser calibration. We are accredited by UKAS, MTA and are Safe Contractor Approved, so you can ensure your machines are in the best working order. You can take a look at all of our services here.

4. Incorrect Height Setting

Placing your lathe in the correct position is essential in the cutting process. The material you are working with determines where you should put the lathe. If working with metal, the machine should be positioned to the chuck’s right and at middle height. Suppose your lathe machine is set to the incorrect height. In that case, it can affect the dimension of the slashing, affecting cutting accuracy.

5. Loose Tailstock

Your machine’s tailstock is another factor that can affect the cutting quality and increase imperfections. Before feeding your workpiece into the chuck, you must ensure the tailstock is locked down. You can do this by screwing all of the loose bolts tight. This way, you will ensure a clean cut and finish.

6. Not Following Safety Regulations

A lathe machine is an extremely powerful piece of machinery, so you need to ensure those using it are thoroughly trained and aware of its dangers. If you know how to operate your lathe correctly, you must ensure that you are following all the correct safety precautions. This will help you maintain a safe working environment for yourself and your workforce. You must wear all of the mandatory protective workwear to minimise the risk of injury. You must also give your full attention to the machine whenever you use it. If you fail to do this, you are at the most significant risk of injury or fatality.

High-Quality Lathe Machines at DTS UK

Account for all of these common pitfalls when using your lathe machine, and you can be sure it will operate safely and precisely. Find the right one for your work needs by exploring our full range of CNC lathe machines. Alternatively, look for more rotary cutting machines with our range of KNUTH manual milling machines also available.

We are also pleased to offer installations, maintenance, repair, and removals with efficiency. Our team of industry experts can help you with their extensive understanding of various tool types. So, if you need any more advice on your machine, don’t hesitate to contact us today. Our friendly team is on hand to offer advice and more information on our lathe machines and services.

Lathe Machine Frequently Asked Questions

Find the answers to our most frequently asked questions for more guidance on operating your lathe machine. Alternatively, our expert team can help you with tailored advice if your query has not been detailed here. You can also learn more about maintenance and repair services from DTS UK.

What is the Lathe Machine Accident Report?

A lathe machine accident report is created after the events of a serious incident in which someone has been injured or could have potentially faced injury when using a lathe. They are produced by the company overseeing lathe work and detail the incident, the risks, the cause and how the machine should be operated safely in future.

This report is distributed across the company and to relevant health and safety bodies.

How to use a Lathe?

Learning how to use a lathe machine is best completed through training and in-person demonstration, especially with the associated risks we have detailed in this guide. However, for those completely unaware or needing a refresher, here are the basic steps for using a lathe machine:

- Set up the lathe machine according to machine/manufacturer specifications. Small lathes should be secured to a bench or work table. Mount the workpiece.

- Select the direction of rotation and turn the lathe machine on. Rotate the lathe at a certain RPM.

- Attempt to give a light pass when slowly moving your tool post near the rotating workpiece.

- Scrape the materials from the surface of the workpiece with your desired cutting tool. Continue until the final result.

Please note: these steps aim to give a basic understanding of the rundown of using a lathe machine, and more detailed instructions should be followed.

What is a CNC Lathe?

A CNC lathe is Computer Numerically Controlled, hence the name CNC. They are used for expert precision machining as it is automatically controlled and moved, ensuring every workpiece cut and shape are identical. For this reason, CNC lathes are typically used to produce small, intricate parts.

A conventional lathe machine is moved manually by the operator. Learn more about the unique specifications in our online guide to CNC lathe machines.

Related

How does a lathe machine work?

4 Reasons your lathe machine needs regular maintenance support