Slant Bed Lathes vs Flat CNC Lathes: Which do you need?

12 Jun 23

CNC lathes are a popular machining tool in the construction industry, and rightly so. Lathes are one of the oldest machine tools widely used across several industries for machine-specific parts. But with many different lathe machine types available, which should you choose?

At DTS UK, we are experts in lathe machines and are pleased to offer a range of options available, including slant beds and flatbed lathe CNC machines. We have also put together an extensive guide into the differences and benefits of each machine to help you make a decision that best suits your industry, team and workshop!

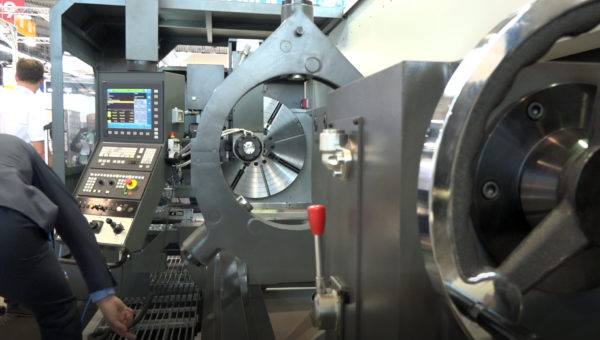

What is a Slant Bed Lathe?

A slant bed lathe is an automated machine tool that delivers high accuracy, high speed, and high precision, utilising a multi-station or power turret. In simpler terms, it is a CNC turning centre with a bed tipped at an angle. It is designed so that chips removed from the workpiece fall away more freely from the machine as it continues the cutting process. Its tipped design also enables larger X-axis travels, making more cutting lines, flexibility, and capacity possible.

A slant bed lathe is a popular choice for mechanical engineering, medical technology, or the automotive industry. This is because it is most suitable for medium-sized components such as aircraft and automobile parts.

Benefits of a Slant Bed Lathe

There are a number of benefits to a slant bed lathe, and we have broken down just a few of our favourites you should consider when deciding on this machine.

- Superior chip removal performance.

- Extended machine life with limited undue stress and wear on the guides.

- Larger X-axis travels.

- Larger part capacity.

- Sturdier base support for the turret.

- Consistent accuracy of all parts machined.

Of course, these benefits might only suit some industries and machining processes, but they are important to note and can improve the efficiency of your workshop. They’re also a good comparison marker when comparing the benefits of a flatbed CNC lathe, which we will further break down for you in the guide.

What is a Flat CNC Lathe?

Arguably more widely used in the machining industry, a flat CNC lathe is an alternative machine structure predominately used for heavy turning. In short, it is the same machine as the slant CNC lathe, but it features a flatbed on this CNC turning centre. It is a popular machine choice for short shafts, complex geometries, discs and more workpieces. As well as this, it can machine internal and external threads in metric or imperial units to suit your requirements.

Different headpieces can also be attached to a flat CNC lathe, allowing it to cut more complex shapes, For example, a rotary head can be attached to drill or mill the end face and circumference of the workpiece.

Benefits of a Flat CNC Lathe

Like the slant bed CNC lathe, there are many advantages and benefits unique to this machine in particular. If choosing a flatbed CNC lathe machine, you can look forward to the following benefits:

- Unparalleled machining range.

- Improved stability and productivity for your workshop.

- Designed to turn the outer circle, slot, and chamfer.

- Capable of drilling, reaming, expanding and rolling.

- Tool automation.

- Able to modify heavy components.

- High rotational speeds.

- Regularly run a high volume of parts.

- Delivers consistent and accurate results every time.

Which Should You Choose?

So, now you know what each CNC lathe is capable of, you can get a clear idea of which might best suit your workshop needs. However, both machines have plenty of benefits and deliver consistently accurate results, so what if you still need help deciding which might be the best option?

To help, we have broken down the differences between slant and flatbed lathes.

Structure and Machine Layout

Of course, the most obvious difference between the two machines is the layout and structure, as one is flat ad the other is on a slant. But what does this mean exactly?

A flatbed lathe has two guide rails parallel to the ground, whereas the slant lathe guide rails intersect to the angles of 30°, 45°, 60° and 75°. Looking at the machines from the side, you can see the difference between the flatbed lathe’s square shape and the slant bed’s right angle. If you’re wondering which shape may best suit your needs, consider the longer X-axis of the slant bed, which can enable more tool alignments and larger capacity.

Performance of Hard Turning

With a flatbed CNC lathe, the cutting force of the tool and workpiece combined to cause a degree of vibration that is not present with the slant lathe. The latter has stronger mechanical resistance to bending and torsion. With the cutting force equal to the direction of gravity of the workpiece, it has a smooth run with limited vibration.

Chip Removal Convenience

As we have touched upon, the slant bed lathe offers an effortless chip removal boosted by the effects of gravity. This is a big advantage that the machine has on the flatbed lathe, which requires manual labour to remove the chips and can also cause wear and tear if left.

Find Out More Today

Have you decided between a flatbed and a slant CNC lathe?

We hope our guide has given you the advice and guidance you need to decide between these two popular CNC lathes. However, both machines will deliver accurate and precise machine parts, so it is up to you to decide which lathe is better suited to your workshop needs.

Explore our range of CMZ slant bed lathes and Gemini horizontal lathe machines available at DTS UK. Alternatively, contact us today with any questions you may have, and our expert team will be happy to help.