GEMINIS GT5: Innovation in Detail

16 Feb 24

As a leading Supplier of Precision Machine Tools, we are constantly at the forefront of showcasing cutting-edge technology that revolutionises manufacturing processes. Today, we delve into the GEMINIS GT5i, a pinnacle of engineering excellence and ingenuity. This machine represents the culmination of meticulous craftsmanship, technological advancements, and a commitment to pushing the boundaries of what’s possible in precision machining.

The GEMINIS GT5: A Closer Look

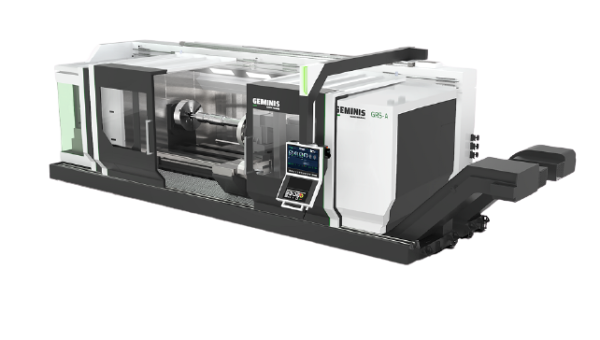

The GEMINIS GT5 is a testament to the relentless pursuit of excellence in precision machining. Renowned as one of the most popular machines in the GEMINIS lineup, it embodies a perfect fusion of robust construction, advanced technology, and ergonomic design.

Our firsthand experience visiting the GEMINIS factory in Spain provides valuable insight into the meticulous manufacturing process behind the GT5. From the moment raw materials are transformed into the finished product, every step is executed with precision and attention to detail.

Innovative Guarding Design

One striking feature of the GT5 is its new guarding and revamped design, marking the dawn of a new generation of GEMINIS machines. This new guarding design enhances the machine’s aesthetics and underscores its durability and reliability in demanding industrial environments.

Heavy Duty Tuning Centre

At the heart of the GT5 lies its heavy-duty, rugged turning centre capabilities. Constructed from a single-piece casting, it exudes strength and stability, making it ideal for a wide range of turning applications. This robust construction is evident in the machine’s ability to easily handle eccentric components.

Improved Ergonomics

During demonstrations, observers are often captivated by the machine’s envelope, which allows them to walk right into its domain. This immersive experience showcases the GT5’s rigidity and stability, highlighting its suitability for even the most challenging machining tasks.

Technical refinements such as the lower bed height and expanded chip discharge demonstrate GEMINIS’s commitment to enhancing user experience and productivity. The ergonomic design facilitates ease of operation and contributes to smoother manufacturing processes.

Precise Power and Optimal Performance

The adoption of a rack and pinion system for axis movement represents a departure from conventional ball screw mechanisms. This choice reflects GEMINIS’s dedication to precision and power, ensuring optimal performance and reliability in every machining operation.

With a generous 1200mm chuck size, the GT5 boasts impressive capabilities, catering to various machining requirements. Whether it’s small-scale components or larger workpieces, this machine delivers consistent results with unparalleled accuracy.

Monitoring and Control

With built-in vibration testing, operators can monitor machining processes in real time, ensuring optimal performance and quality. The Siemens touchscreen control system provides intuitive navigation and seamless integration with digital workflows. By leveraging these innovative features, manufacturers can achieve unparalleled efficiency and precision in their operations.

Unleashing the Future of Precision Machining with the GEMINIS GT5

From its inception in the GEMINIS factory in Spain to its demonstration on the trade show floor, the GT5 has captured the imagination of manufacturers worldwide. Its robust construction, advanced features, and ergonomic design underscore its position as a leader in the field of precision machining.

Built on a foundation of quality and innovation, the GEMINIS GT5 is more than just a machine; it’s a symbol of progress and ingenuity. As industries evolve and demands grow, the GT5 remains a steadfast companion, empowering manufacturers to push the boundaries of what’s possible.

With DTS by your side, you can confidently and precisely embrace the future of manufacturing. Experience the excellence of the GT5i and discover a world of endless possibilities in precision machining. Explore our GEMINIS collection at DTS UK, and don’t hesitate to contact us for more information.

GEMINIS GT5 FAQs

What industries can benefit from the GEMINIS GT5 Precision Machine Tool?

The GEMINIS GT5 is versatile and adaptable, catering to a wide range of industries, including aerospace, automotive, oil and gas, and more. Whether you’re producing small components or large-scale parts, the GT5 offers precision and efficiency for various applications.

What sets the GEMINIS GT5 apart from other precision machine tools?

The GT5 stands out for its robust construction, advanced technology, and ergonomic design. With features such as a modular turret, vibration testing capabilities, and a Siemens touchscreen control system, the GT5 offers unmatched performance and reliability in precision machining.

How user-friendly is the GEMINIS GT5?

The GT5 is designed with user experience in mind. With intuitive controls, ergonomic features, and real-time monitoring capabilities, operators can navigate the machine with ease and confidence, maximising productivity and efficiency.

Is the GEMINIS GT5 suitable for both small-scale and large-scale manufacturing operations?

Yes, the GT5 caters to a wide range of manufacturing needs, from small-scale production runs to high-volume manufacturing. With its versatility, adaptability, and precision, the GT5 is ideal for businesses of all sizes seeking uncompromising quality and performance in their machining operations.