How to Use a Lathe Machine?

11 Jun 24

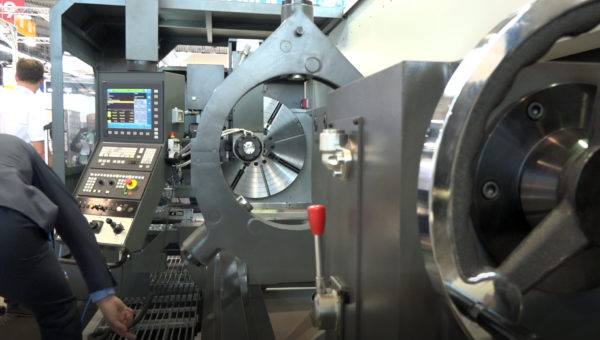

Whether you’re a beginner or an experienced machinist, mastering the lathe machine is essential for creating precise and intricate projects. From the seamless curves of a wooden bowl to the intricate details of a metal part, the lathe machine opens up a world of possibilities. In this guide, we’ll walk you through the essential steps of setting up, operating, and maintaining your lathe machine safely and effectively.

Stage 1: Preparing Your Workspace

A well-prepared workspace is the cornerstone of successful lathe operation. Think of it as setting the stage for a performance: everything must be in place to ensure smooth, efficient, and safe machining. Let’s dive into the essential steps to get your workspace ready.

Clearing the Workspace

Imagine walking into a clutter-free workshop, where every tool is in its place, and there’s ample room to manoeuvre. This is not just about aesthetics; a tidy workspace significantly reduces the risk of accidents and enhances your focus.

- Start with a Clean Slate: Remove any unnecessary tools, materials, and debris from your workspace. This includes clearing and sweeping the floor and wiping down surfaces. A clean environment prevents tripping hazards and ensures you can find your tools when you need them.

- Organise Your Tools: Place your tools in a logical order, preferably within easy reach. Use tool racks, pegboards, or drawers to keep everything organised. This setup mimics a chef’s kitchen, where everything is within arm’s reach, enabling you to work more efficiently.

- Clear the Path: Ensure that the area around your lathe machine is free from obstructions. This will not only provide a safer working environment but also make it easier to move around and access different parts of the machine.

Stabilising Your Lathe Machine

Stability is crucial when working with a lathe machine. An unstable lathe can lead to inaccurate cuts and even dangerous situations. Think of your lathe as the foundation of a house – it needs to be rock solid.

- Check the Surface: Ensure that your lathe is placed on a flat, level surface. Use a spirit level to check for any tilting or unevenness. Adjust the feet of the lathe if necessary to achieve a perfectly level setup.

- Secure the Lathe: Once you have a level surface, make sure the lathe is firmly anchored. Depending on your setup, you might bolt the lathe to the floor or a heavy, stable bench. This prevents any movement during operation, which is crucial for precision work.

- Vibration Dampening: Consider adding rubber mats or vibration-dampening pads under the lathe. These can absorb minor vibrations that could otherwise affect the quality of your work. This is especially important if you’re working on a concrete floor, which can amplify vibrations.

Stage 2: Setting Up the Lathe Machine

Now that your workspace is primed and ready, it’s time to delve into the nitty-gritty of setting up your lathe machine. Whether you’re a beginner or a seasoned pro, mastering the fundamentals of lathe setup is essential for achieving precise and consistent results. Let’s break it down step by step.

1. Mounting the Chuck:

Insert the chuck key into the chuck and rotate it clockwise to tighten the jaws. Make sure the chuck is securely attached to the spindle, as any looseness can lead to inaccuracies during machining.

2. Preparing the Workpiece:

Before mounting the workpiece, ensure that it’s clean and free from any defects or irregularities. Align the workpiece with the centre of the chuck and tighten the jaws securely. This step is crucial for achieving symmetrical and accurate machining.

3. Tool Selection:

Consider the material and desired outcome when selecting your cutting tools. Carbide inserts are ideal for general-purpose machining, while high-speed steel tools offer versatility and durability.

4. Tool Setup:

Secure the chosen tool onto the tool post, ensuring it’s properly aligned and tightened. Adjust the height and angle of the tool to suit your machining requirements. This precision setup will ensure smooth and accurate cutting.

Stage 3: Operating the Lathe Machine

With your workspace prepared and your lathe machine set up, it’s time to embark on the actual machining process. Operating a lathe machine requires a blend of technical skills and careful attention to detail. Let’s walk through the key steps to ensure a smooth and successful operation.

- Turn on the Power Switch: Locate the main power switch and turn it on. This supplies power to the lathe machine.

- Activate the Coolant Pump: If your lathe machine is equipped with a coolant system, activate the coolant pump to ensure proper lubrication and cooling during machining.

- Adjust Spindle Speed and Feed Rate: Set the spindle speed and feed rate appropriately based on the material you’re working with. Your lathe machine’s manual has recommended settings for different materials.

- Engage the Spindle: Pull the spindle control lever towards you to engage the spindle. Gradually increase the speed until you reach the desired operating speed.

- Position the Cutting Tool: Move the carriage to position the cutting tool at the desired starting point on the workpiece. Ensure that the tool is properly aligned with the workpiece to achieve accurate cuts.

- Advance the Cutting Tool: Slowly advance the cutting tool towards the workpiece until it makes contact. Use the handwheel to control the movement and ensure a smooth engagement.

- Begin Cutting: Once the tool makes contact, begin the cutting operation by feeding the tool into the workpiece at the desired depth and speed. Maintain a steady hand and consistent feed rate to achieve clean and precise cuts.

- Check Coolant Flow: Ensure that the coolant is flowing properly to prevent overheating and prolong the life of your cutting tool. Adjust the coolant flow as needed to maintain optimal conditions.

- Inspect the Workpiece: Regularly inspect the workpiece for any signs of damage, excessive wear, or inaccuracies. This allows you to make real-time adjustments to achieve the desired outcome.

- Monitor Cutting Tool Condition: Keep an eye on the cutting tool for signs of wear or damage. A worn tool can affect the quality of your cuts, so replace it as necessary.

- Adjust Spindle Speed and Feed Rate: Based on the feedback from your inspections, adjust the spindle speed, feed rate, or cutting tool position to optimise the machining process.

Explore Lathe Machines at DTS

Operating a lathe machine is a blend of technical skills, careful preparation, and a keen eye for detail. By following the steps outlined in this guide, you’ll be well on your way to creating precise and beautiful machined pieces.

Ready to take your lathe machining skills to the next level? Explore our extensive range of high-quality lathe machines at DTS UK. Visit our website today to find the perfect lathe machine for your workshop and start bringing your creative visions to life confidently and precisely.

Did you know we also offer lathe machine maintenance and repairs? Get in touch to find out more!

Lathe Machine FAQs

What is a lathe machine used for?

A lathe machine is used to shape and machine various materials, such as wood, metal, and plastic, by rotating the workpiece against a cutting tool. It’s commonly used for creating precise parts, such as cylindrical shapes, threads, and intricate designs.

What safety precautions should I take when operating a lathe machine?

Safety is paramount when operating a lathe machine. Always wear appropriate personal protective equipment (PPE) like safety glasses and gloves. Ensure the workspace is clean and organised, and check that the lathe machine is stable and properly set up. Follow the manufacturer’s guidelines for operating the machine and handling materials.

How do I choose the right cutting tool for my project?

Choosing the right cutting tool depends on the material you’re working with and the specific operation you’re performing. Carbide inserts are great for general-purpose machining, while high-speed steel tools offer versatility. Consider the hardness and type of material, as well as the desired finish and precision of the cut.

Related Articles

Lathe vs Milling Machines: What’s the Difference?