The DTS UK Lathe Glossary

18 Aug 20

The world of lathes is filled with terminology you may be unfamiliar with. This can make research complex and difficult to interpret as it may use terms you are unfamiliar with. In this guide, we’ll provide a glossary of key terms you may come across when working with lathes.

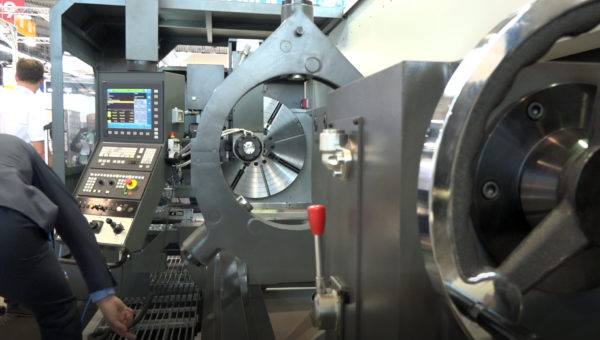

Section 1: Lathe Components

Lathes consist of many components. In the first section of this glossary, we have defined some of the most commonly referenced and important components.

Headstock

The headstock is the component of a lathe responsible for rotating the workpiece. It uses bearing to allow the workpiece to rotate against stationary cutting tools.

Spindle

The spindle is the rotating axis of a lathe and is part of the headstock. It is hollow with threading on the outside. They are driven by a pedal or a motor depending on the type of lathe.

Faceplate

The faceplate is a part of a lathe used to hold a workpiece in place. Faceplates are not present in all lathes but are common among many types and models. Before use, a workpiece will be secured to the faceplate. This is typically done by running a bolt through both the workpiece and faceplate.

Bed

With the exception of CNC lathes where the bed is vertical to avoid build-up of swarf, a lathe bed is a horizontal beam. Many of the components of a lathe are placed on the bed, as is the workpiece.

Cutting Tool

Cutting tools are tools which are held in place while the workpiece is applied to them. The workpiece is then rotated around an axis. Lathe tools give a workpiece symmetry about that axis through actions such as sanding and turning.

Section 2: Materials

There are several materials you will come across when working with lathes which may be less common in other areas. In addition to the materials you will use as workpieces there are also the materials used for lathe tooling. We have listed the most common lathe tooling materials below.

HSS

HSS is shorthand or High-Speed Steel. This is a material commonly used in cutting tools. It is easily sharpened on a grindstone and is inexpensive.

Cemented Carbide

Cemented carbide is a hard material used in cutting tools. Cemented carbide is made up of fine particles of carbide and a binder metal.

Section 3: Other Lathe Terms

In addition to lathe components and materials, there are some other terms not often used other than in reference to lathes. We have outlined some of the ones you may need to know below.

Carbide Insert Tooling

Carbide insert tooling are tools using replaceable carbide inserts. Carbide is more expensive than other tools. By using inserts you can use carbide as the cutting interface without the cost of creating the entire tool from carbide. Replacing the cutting interface only requires replacing the inserts and not the entire tool.

Swarf

Sometimes referred to as chips, swarf is the material removed from a workpiece. This term is used regardless of the process used i.e sanding, turning, or cutting the waste material is called swarf.

Additional Lathe Terminology Guides

If you are looking for some guidance beyond this glossary check out our guide to types of lathes. They breakdown more terms and offer a variety of insights about the different uses of the various lathes and milling tools available.

Navigating lathes properly and maximising their use requires the knowledge of some industry-specific jargon. With the definitions in this guide and the additional guides referenced you are better equipped to handle lathes and interpret lathe related literature.